Historical Gose Recipe Part 4

The next one is one of the biggest sources I found beside a book about the brewing history of Goslar. The source for this one is a Goslar newspaper from 1882 and was written in 1869. A fellow homebrewer posted this on his website.

In order to preserve the brewing practise of the Goslarsche Gose I take the opportunity to document it. Over 40 years the brewing practise of the Gose was not observed and only a few persons know about it. In order to explain it some details have to be mentioned before.

As you know there are 301 sanctioned brewing entities in Goslar. In old times the same amount of brewhouses where there. In the year 1790 there where only 60 left, 1840 only 30. In old times the sanctioned brewing entities brewed in a specific order one at a time. This happens at an arbitrary place but usually the brewing time was leased to another brewer. But who was using the brewing rights (Brauzeit) for their own is called Actueller Brauer, there where 6 of this brewers in 1816 which where transfered 1840 to the active brew houses. In these active brew houses the people brewed with oversight from brewing directorate.

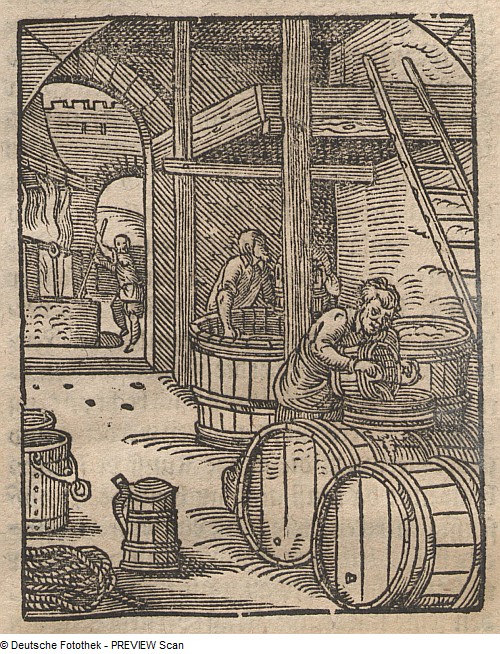

The active brew houses consisted of two big brewing pots and the needed brewing equipment. When it was time to brew the people got a rent compensation of 60 Thlr for a brew with 3 1/2 Wispel input.

The hot word from the pan will be transfered into open vessels in the cellar. These vessels are getting so hot and damp that is nearly imposible to transfer hot wort into the cellar. This lead to a so called flying brewery. For this 2 brewing pans existed and while brewin is in progress the second pan will be brought to another bew house with a sledge. The pan is then bricked in.

Only since the beginning of this century we have began to brick in the pan. In old times the same would sit on a big tripod (Stridden) and slate plates would be placed around the pan. These big slate plates where broken in a slate pit. After the pan is bricked in it would be filled with water and a fixed amount of spruce twigs where cooked. With this spruce infusion the brewing vessels (bottiche) as well as the cellar items like big open vessels (Wannen, Tubben) where cleand and sealed.

The wood that was needed for brewing was usually prepared earlier and drove to the brewhouse.The brewing equipment was restricted most of the time. The pan and the mash and lauter tun where placed in a line. The pan higher than the tuns but without drain valve since everything was ladled.

The wheat that was bought from brewing director was delivered to diefferent brew houses to malt it. Only special reserves where stored in common storage areas. The malting was mostly done by widdows and old virgins, which where owners of active brew places. They got payed 2 Thaler for their work and the rent.

Usually 2 Wispel where put into the swell tun and were covered with water. In this water the wheat hat to soak so lang till a white milky fluid came out of the kernels when you squeezed them. Because there was the belief that the sweeling process was important for the solubility of the wheat and not the germination process. The swell tun was covered with small air bubble since the sweelwater was coming in a more or less foul fermentation. The wheat was no longer able to germinate since it was to wet from the swelling. So it was put in small piles on the floor to dry. When the wheat was dried enough that he had only so much moisture to germinate it would be transfered to house floor in the growing bed. There the wheat would lie so long till the germs would show. In between it needed to be raked regulary. Somtimes the raking was not done and the wheat was growing together. You could smell where the raking was not done. In order to brew with it it had to be teared with hands or a strong rake. The now seperated malt would be left to dry and than moved to one side when complete.

At the beginning of the brew day 3 1/2 Wispel malt where brought to the mill 12 hours before. There they where moistened with water and milled. The milling was done corse in order to aid the lautering. The milling had to be done in authorized mills like Kegeworth or Frankenberger Malt mill with the obervance of a cellar women.

It was a good sign when the mill was not getting stuck from the glue in the wheat. If that happens they had to get the milling stone away and chop away the glue from the malt. This would come either from malt that was moitened too much or not dried enough in the first place.

While water in the pan is heated the lauter tun (Seihbottich) is prepared by adding a layer of rye straw to the bottom and than placing fitting wooden sticks called barlen over it. The wooden sticks are fixed with small bars under the ceiling. Between the pan and partly covered by the lauter tun there was the Werthstein (Grand) which was a bit vessel hewn from sandstone. To open and close the lauter tan a wooden peg was used. This peg was wrapt with a straw crest and some stones where layed around it. It reached the bottom of the lauter tun.

After enough cold water was added to the lauter tun, hot water from the pan and milled malt was added and mashed. The mashing happened with the help of Krücken (sticks) or mash sticks (8 foot long sticks with a grid at the end). The whole brewing personal except the water warden had to help with mashing. The water warden was accountable that enough water was available for the brew day.

While the first mashing there was usally a pause where a song where sung. After the mash was sitting for one hours and had settled the wort was let into the Werthstein und and then in the wort tun. While that is happening the pan is filled with water and brought to a boil. If the lauter is complete the second pan would be transfered into the lauter tun and mashed. The wort that was first collected was transfered into the pan and boiled for two hours. This was called the Beste Krug. After boiling it was filtered through a hop basket that was filled with spruce branches and then transfered to the cellar via chutes.

From the wort of the Beste Krug 1-2 Ohm where put into a copper kettel and in the cellar when missing in big vessels (Stannen) which contained a bag of wormwood and cinamon. These spices made for a special taste and the so called Frehmtenbestekrug was the best product of the Goslarsche Gose and was only given out to the best customers.

When lautering a lot of mud and slime parts where brought into the pan. These parts came together to big lumps and where fished out of the pan with foam laddles. The rest of them where filtered through the spruce branches. Even with these measures the beer hat a lot of glue and was looking like pea soup and had the peculiar taste of spruce needles.

As mention before everytime the lauter was complete the wort was collected in the wort tun. Everytime the beer was finished cooking the pan was filled with water and put onto the spent grain and mashed again. In this fashion following qualities where produced:

1. Werth (Bestekrug)

2. Werth

3. Werth

4. Werth (Hüppig)

To the Hüppig some malt or colourmalt was added. At last the Hopfenwerth was produced. The Pan was filled with 1/3 of water and usually 60 Pounds of Hops to 3 1/2 Wispel malt. And since there was a lot of time this was cooked quite long. This process was called Hopfenschmoren. Every type of Gose was put into marked vessels and only when selling the different types where mixed according to the sail price.

The Hüppig and the spent grain where sold after the brewing day. To announce that the brew house had beer to sell a Lof (a stick with beatiful painted wine grape on its end) was hung out.

Since the beer was not innoculated, the fermentation happened by itself or a thick layer of mold developed. The thicker the leather like skin was the better the beer was keeping since the mold layer was keeping oxygen from getting into the beer. Only after the beer was given away the yeast was pitched.

Here again the magic number for malt is 3 1/2 Wispel of wheat malt. Another number is 60 pounds of hops, this translates to roughly 30 kilos of hops. So when you add it up you get 2250 kg malt and 30 kg hops that is 13 g hops per kg malt. Now I can at least somehow estimate the amount of hops that where added.

Other Informations in this descriptions that are notable is the malting which describes that it was floor malted wheat. I don’t know enough of malting to say if it lead to a good quality malt.

One big point here was the big use of spruce twigs for a lot of things like cleaning, lautering and filtering aid after cooking. Also interesting is that the hops where not cooked in every wort but where cooked in one liquid and this extract was then distributed to the other brews. Another detail that was not mentioned before was the rye straw that was used.

The other point is that the wort was not innoculated and some kind of pellicle formed on it.